Finger Jointing Process

Finger jointing is a cutting-edge woodworking technique where small wood pieces are joined to form strong, durable panels. Our finger-jointed timber is crafted using CP Teak, Sal, and Margosa, offering strength and sustainability.

- Precision with Imported Machines

- Eco-Friendly Production

- Enhanced Durability

- Perfect for Large Applications

Seasoning & Chemical Treatment

Proper seasoning is essential to improve the quality and performance of wood. We ensure that every piece of timber undergoes rigorous seasoning and treatment processes to maintain structural stability and prevent defects.

- Controlled Seasoning for Stability

- Chemical Treatment for Protection

- Machine-Finished for Accuracy

Features

Fine Sanded &

Ready to Use

Shrinkage &

Warpage-Free

Superior Strength

& Durability

Fully Seasoned

Timber

Termite, Fungus &

Borer Resistant

Precision

Manufacturing

Water-Resistant

& Weatherproof

Cost

Effective

Available in Multiple

Sizes & Thickness

Excellent Screw &

Nail Holding Capacity

Eco-Friendly

& Sustainable

Accurate Engineering: Machine-finished

Why Our Certifications Matter to You?

- Assurance of Quality: Our certified performance metrics guarantee that our timber will last for years, whether used for windows, doors, or structural applications.

- Peace of Mind: With rigorous testing against pests, moisture, and mechanical stress, our customers can trust our timber to stay durable and reliable in any environment.

- Eco-Friendly and Sustainable: Certifications ensure that our timber contributes to environmental sustainability, providing an eco-conscious option without compromising on quality.

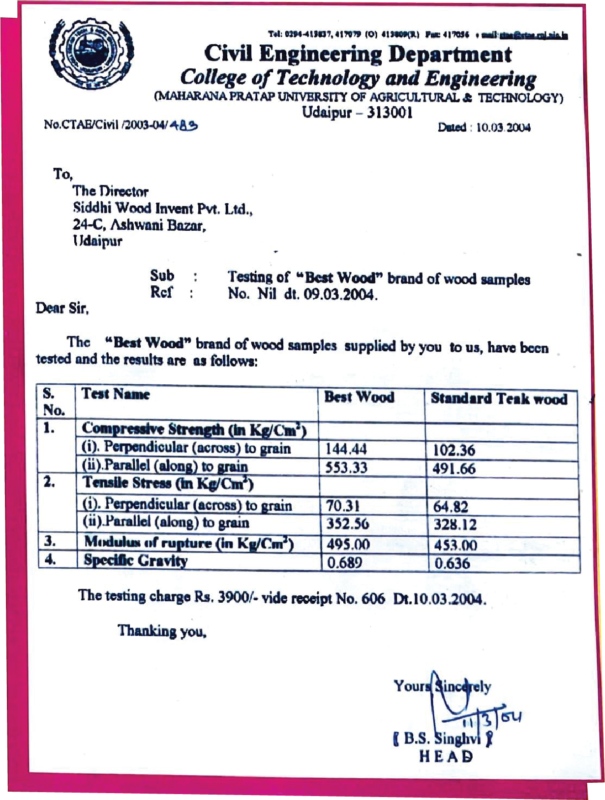

Technical Report & Certifications: Quality You Can Trust

CTAE Testing Report

The Civil Engineering Department at the College of Technology & Engineering (CTAE), Udaipur, has technically tested our timber products, including finger-jointed CP teak, Assam teak, and pine wood. Key Results from the Test Report:

- Compressive Strength (kg/cm²)

- Shear Strength (kg/cm²)

- Moisture Content (%)

Certifications That Guarantee Reliability

We are committed to upholding international quality standards and ensuring that every piece of timber we deliver meets the highest benchmarks of sustainability and performance. Our products are backed by the following certifications and quality assurances:

- Certified Resistance to Termites, Fungus, and Borers

- Eco-Friendly Manufacturing Certification

- Dimensional Stability Certification

- ISO Standards for Manufacturing Precision

Advanced Testing by Automated Machines

Our products undergo multiple stages of quality control using state-of-the-art automated machines that eliminate human error and ensure uniformity in every piece of timber we manufacture. These machines test:

- Nail and Screw Holding Capacity

- Four-Side Moulding and Planing Precision

- Shrinkage and Warpage Testing

Connect With Us Instantly!

Have questions or need assistance? We’re just a message away! Let's make your experience seamless!